Did you know?

One rotation of a single turbine will generate enough electricity to power a typical New Jersey home for more than 19 hours.

Electrical energy can be generated by rotating magnets inside a coil of conductive wire. The big question is how to achieve that rotation.

In conventional power stations, fossil fuels like coal, gas and oil are burnt to heat water, producing high pressure steam that can drive a turbine and, in turn, an electrical generator.

Unfortunately, this also produces carbon dioxide and other harmful emissions, as well as relying on finite resources that need to be constantly extracted from underground and transported to the power station.

In a wind turbine, the rotation is achieved through the clean, natural, and ultimately unlimited power of the wind.

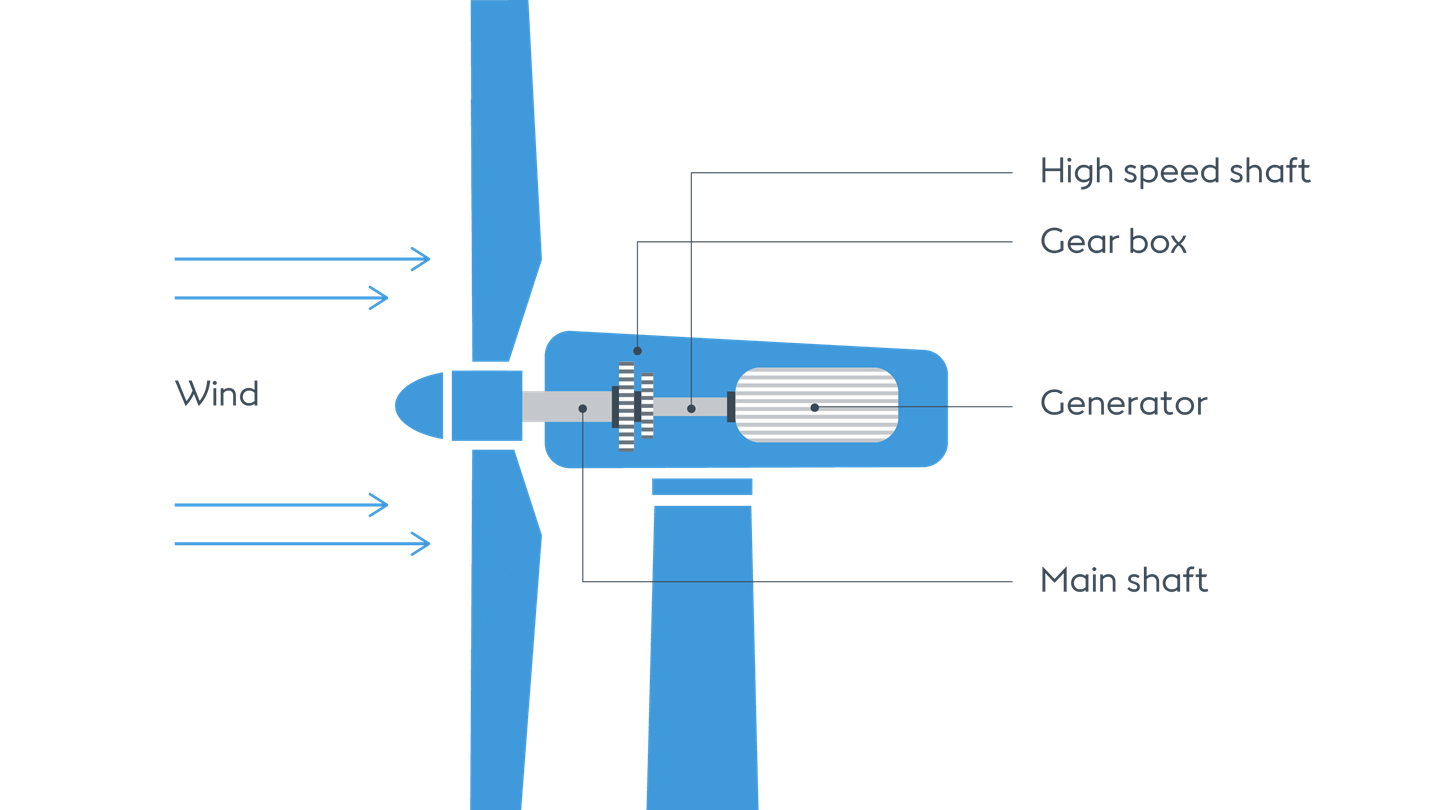

To capture wind energy, the top part of the turbine is turned to face the wind, the three blades are set at exactly the right angle, and the movement of the air past them causes them to rotate.

Within the nacelle – the non-rotating part on top of the turbine – the blades’ rotation is passed through a drive shaft, often via gear box, to turn magnets inside a coil of wire. This generates an alternating current of electricity.

One single wind turbine can generate a few megawatts (MW) of power. That’s a lot compared to the power needed to light a home, for example. But it’s still much less than the steam turbine in a conventional power station.

That’s why wind turbines are grouped together to form a wind farm. This can be thought of as one big power station – but one that doesn’t create any emissions when it generates electricity.

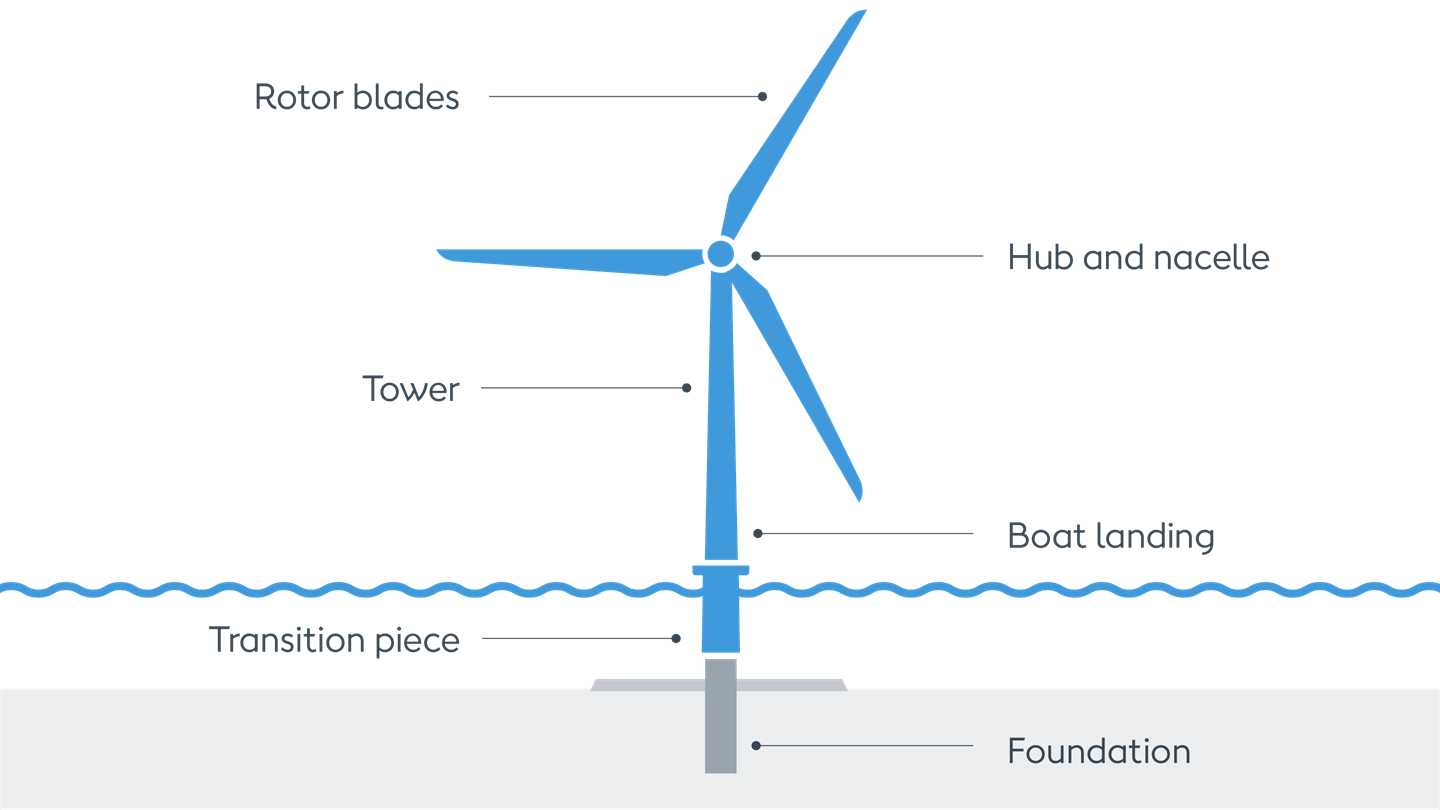

An offshore wind farm is made up of many turbines spread out over a wide area of ocean. Each one is firmly fixed to a foundation piece on the seafloor, with a tower that extends up into the air where the blades can make use of higher wind speeds.

Did you know?

One rotation of a single turbine will generate enough electricity to power a typical New Jersey home for more than 19 hours.

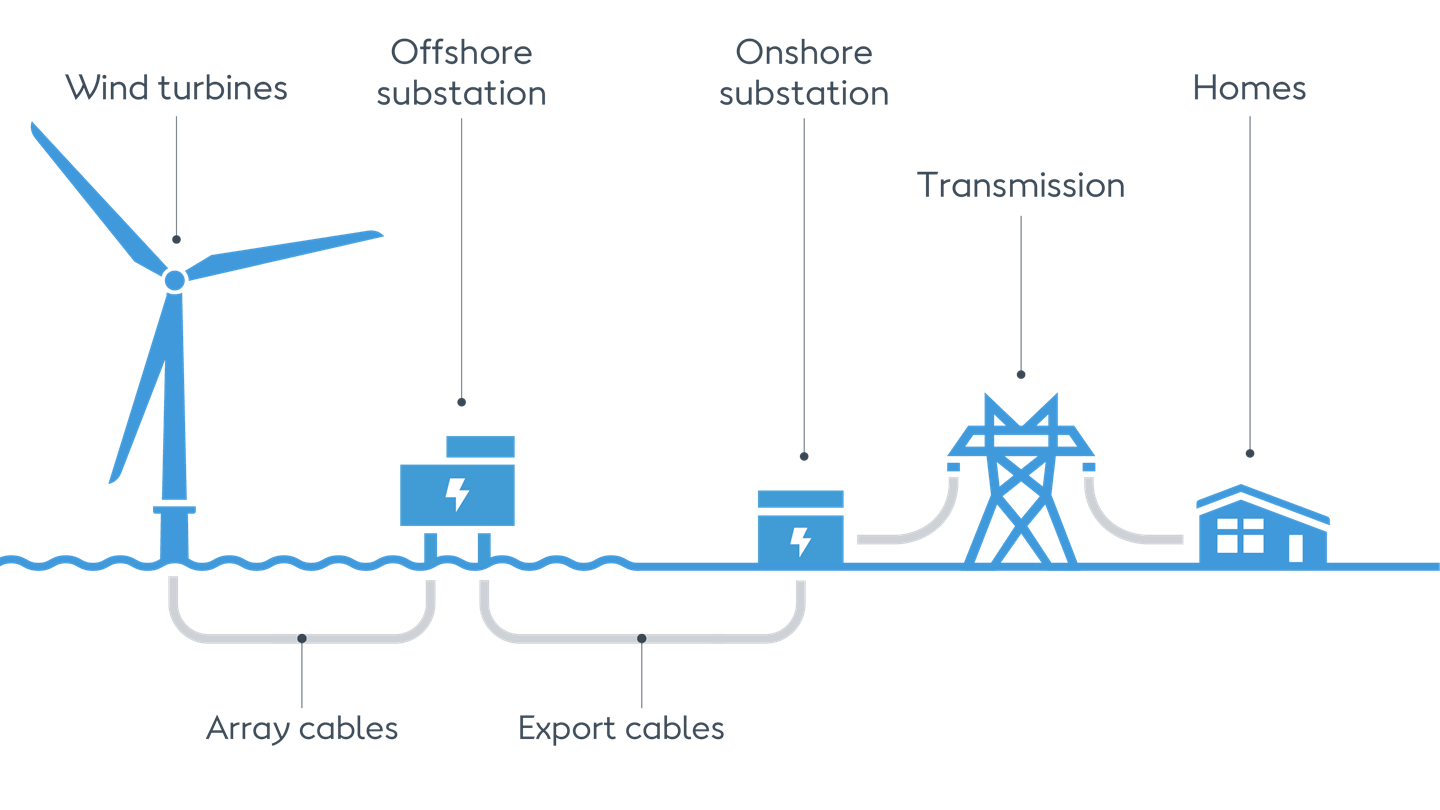

Each turbine sends its power through cables down the tower and under the seabed to an offshore substation. Here the energy is stepped up to a higher voltage ready to send ashore via high voltage cables. Higher voltage means less energy is lost in transmission.

On land, another substation adjusts the voltage again so that the electricity can be fed into the grid and distributed via power lines to the homes and business that need it.

A wind farm is expected to be in commercial operation for at least 25 years. During this time, it needs to be serviced and maintained to keep working things optimally, prevent faults, and fix anything that goes wrong.

This work is done by a team of highly skilled wind turbine technicians. These technicians use their knowhow, along with the latest technological innovations, to keep everything working as it should be, troubleshooting technical problems as they arise, and carrying out inspections.

Because offshore wind farms are usually located far from the shore, crews of technicians often live on a service and operations vessel – a floating staff hotel – for two weeks at a time. This means they can easily access the turbines that need attention – and take two weeks’ well-deserved leave in between shifts.

Did you know?

As well as creating jobs for turbine technicians, offshore wind generates work, opportunities and economic benefits throughout the local communities where it is built.

When a wind farm eventually reaches the end of its lifespan, it is either decommissioned, life-extended, or repowered.

While life extension involves repairing and maintaining the existing turbines for further years of service, both decommissioning and repowering mean removing the old turbines.

Repowering involves replacing the old turbines with the latest larger and more efficient models, while decommissioning means completely dismantling the wind farm.

In either case, the old turbines need to be removed. At present, up to 95% of a turbine can be recycled, with the lightweight blades proving more challenging. In 2021, Ørsted committed to send no more blades to landfill, but instead to explore options for reuse and recycling.

Recycling wind turbines

Today, 85-95% of the material from a decommissioned turbine can be recycled.